Oil, often referred to as liquid gold, plays a pivotal role in our daily lives. Whether it’s the oil used for cooking, lubrication, or cosmetics, the process of extracting this valuable substance is a fascinating blend of tradition and innovation. In this comprehensive guide, we will delve into the diverse world of oil extraction machines. We’ll explore the mechanics, efficiency, and environmental impact of various methods, giving you the knowledge to make informed decisions for your oil production needs.

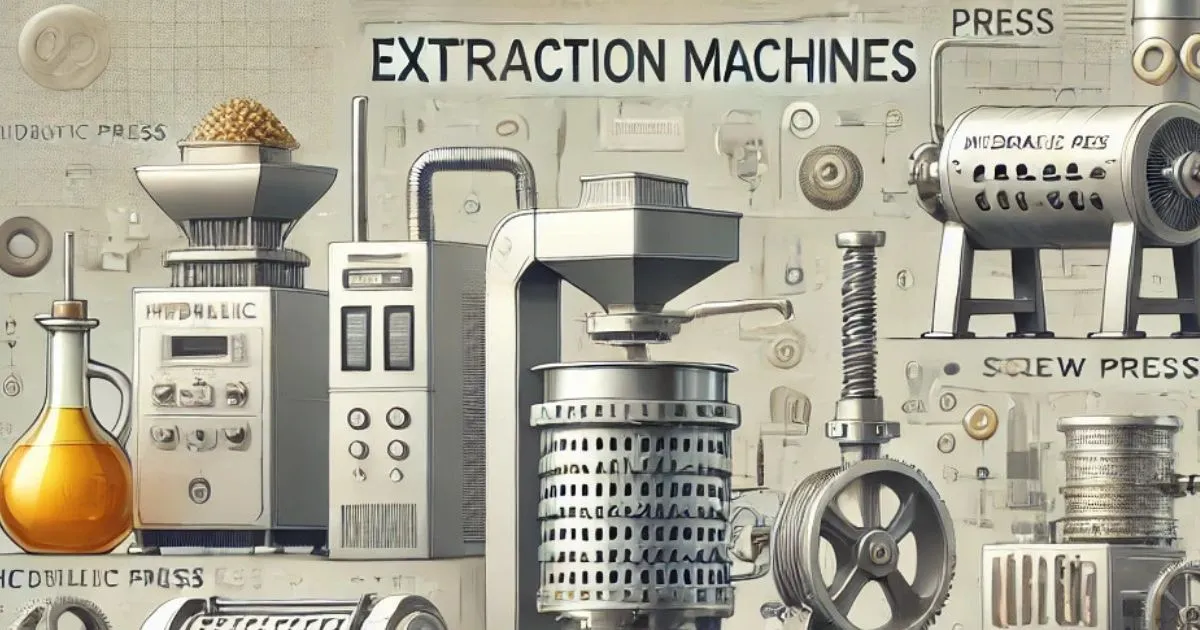

The Role of Extraction Machines in Oil Production

Oil extraction machines are the backbone of the entire oil industry. They are responsible for transforming raw materials, such as seeds, nuts, or fruits, into the precious oils we rely on. These machines automate and streamline the extraction process, making it efficient and scalable.

Selecting the right oil extraction machine is crucial for achieving the desired quality and quantity of oil. Different machines are designed for specific purposes, and understanding their mechanics and applications is key to optimizing your oil production process.

Expeller Press Machines

Mechanics and Operation of Expeller Press Machines

Expeller press machines, often known simply as “expellers,” are a cornerstone of oil extraction. These mechanical devices work on the principle of pressure and friction to extract oil from various raw materials. The process involves feeding the raw materials into a cylindrical chamber, where a screw press pushes it against a perforated cage. As the materials are compressed, oil is squeezed out and collected.

Expeller press machines are renowned for their simplicity and reliability. They are particularly suited for producing unrefined oils, retaining the natural flavors and nutrients of the source material. This makes them a preferred choice for those seeking a more authentic and minimally processed oil.

Interested in a deeper dive into expeller pressing? You can explore the “Expeller Pressing” sub-topic in our “Unrefined Oil Extraction Methods” blog post.

Cold-Pressing Machines

Design and Working Principle of Cold-Press Machines

Cold-press machines, as the name suggests, operate without the application of heat. These machines are designed to extract oil at lower temperatures, preserving the oil’s flavor and nutritional value. They are commonly used for extracting oils from delicate ingredients like olives, seeds, and nuts.

The cold-pressing process involves placing the raw material into a hydraulic press, where pressure is gradually applied. The oil is released as a result of this pressure, without the need for external heat sources that can degrade the oil’s quality.

Compared to other extraction methods, cold-pressing is known for producing oils with superior flavor and nutritional profiles. It is a popular choice among health-conscious consumers and gourmet chefs.

Wants to know more about the efficiency and product quality of cold-pressing method? Explore more in depth about “Cold-Pressing Method”

Traditional Extraction Tools

Exploring Traditional Machines

Before the advent of modern machinery, oil extraction was a labor-intensive process relying on traditional tools. Stone presses and wooden screw presses were among the early contraptions used for this purpose. These machines hold historical significance and cultural importance in various regions around the world.

Stone Presses: Stone presses, also known as stone mills, date back centuries and were primarily used for olive oil extraction. They consist of a large stone wheel that rolls over olives, crushing them and releasing the oil.

Wooden Screw Presses: Wooden screw presses were another early innovation. They involved a large wooden screw that was turned to apply pressure to the raw material, forcing out the oil.

While these traditional machines have largely been replaced by more efficient and automated options, they continue to be used in some artisanal and heritage oil production processes.

Solvent-Based Extraction Equipment

Overview of Solvent-Based Extraction Equipment

Solvent-based extraction is a widely employed method for obtaining oils from various sources. In this process, organic solvents like hexane are used to dissolve the oil from the raw material. The resulting mixture is then separated, with the solvent evaporating, leaving behind the extracted oil.

Solvent-based extraction equipment is sophisticated and designed to handle large-scale oil production. It includes extraction tanks, evaporators, and condensers. This method is particularly efficient for extracting oil from oilseeds with low oil content, such as soybeans.

Pros of Solvent-Based Extraction:

- High oil yield: Solvent-based extraction can efficiently extract oil even from materials with low oil content.

- Fast extraction: It’s a rapid method suitable for industrial-scale production.

- Versatility: It can be used for a wide range of raw materials.

Cons of Solvent-Based Extraction:

- Environmental concerns: The use of organic solvents raises environmental issues, including pollution and safety hazards.

- Quality concerns: The oil extracted through solvent-based methods may require additional refining to remove solvent residues and impurities.

The choice between solvent-based extraction and other methods depends on factors such as the type of raw material and the desired oil quality.

Modern Innovations in Oil Extraction

In the pursuit of efficiency, quality, and sustainability, the world of oil extraction has seen remarkable innovations in recent years. These advancements have revolutionized the industry and offer exciting possibilities for both producers and consumers.

Technological Advancements in Oil Extraction Machinery

- Supercritical CO2 Extraction: This cutting-edge technology uses carbon dioxide in its supercritical state to extract oils. It’s prized for its ability to extract oils without using heat, preserving the oil’s quality and purity. Additionally, CO2 is a safe and eco-friendly solvent.

- Ultrasonic Extraction: Ultrasonic waves are employed to break down cell walls, facilitating the release of oil. This method is highly efficient and can be used for a wide range of raw materials.

- Enzyme-Assisted Extraction: Enzymes are used to degrade cell walls and release oil. This method is gaining popularity for its eco-friendly approach and minimal use of heat.

- Automation and Robotics: Modern extraction facilities are increasingly incorporating automation and robotics to streamline the production process, reduce labor costs, and improve overall efficiency.

Eco-Friendly and Sustainable Innovations

The importance of sustainability in oil extraction cannot be overstated. With growing environmental concerns, many manufacturers are developing eco-friendly machines and processes.

Some notable innovations include:

- Recycling and Waste Reduction: Efforts to minimize waste and recycle byproducts have become a priority. For example, waste materials like press cakes can be turned into valuable resources, such as animal feed or biofuels.

- Energy-Efficient Equipment: Manufacturers are designing extraction machines that consume less energy, reducing their carbon footprint.

- Biodegradable Solvents: Research is ongoing to find biodegradable alternatives to traditional solvents, reducing the environmental impact of solvent-based extraction.

These innovations not only enhance the efficiency and quality of oil extraction but also contribute to a more sustainable and eco-conscious industry.

Considerations for Selecting Machines

When choosing an oil extraction machine, several factors come into play. The decision should align with your specific oil production needs, the type of raw materials you work with, and your sustainability goals.

Factors Influencing the Choice of Extraction Machines

- Type of Raw Material: Different materials require different extraction methods. For example, seeds, nuts, and fruits may require cold-pressing, while oilseeds with low oil content may benefit from solvent-based extraction.

- Production Scale: Are you a small-scale artisan producer or a large industrial operation? The scale of production will dictate the size and complexity of the machine you need.

- Oil Quality: If preserving the natural flavor and nutrients of the oil is paramount, methods like cold-pressing or supercritical CO2 extraction may be preferred.

- Environmental Impact: Consider the environmental footprint of your chosen method. If sustainability is a concern, explore eco-friendly options and ensure proper waste management.

- Cost Considerations: Your budget plays a significant role in the selection process. While advanced technology can enhance efficiency, it may come with a higher initial cost.

Matching your equipment to your specific needs is essential for optimizing your oil production process and achieving your desired product quality.

For more insights into choosing the right extraction method, you can also refer to our guide “Unrefined Oil Extraction Methods“.

Efficiency, Quality, and Environmental Impact

As the demand for high-quality oils continues to grow, concerns about efficiency, product quality, and environmental impact are at the forefront of the industry. The choice of extraction machine directly influences these factors.

Efficiency

Efficiency is a critical consideration for any oil production operation. Efficient machines maximize oil yield while minimizing waste. Expeller press machines and solvent-based extraction equipment are known for their efficiency, each suited to specific scenarios.

Cold-press machines, on the other hand, may have lower extraction efficiency but excel in preserving the oil’s quality. Supercritical CO2 extraction, with its ability to extract without heat, also falls into the category of efficient methods.

Quality

Oil quality is a paramount concern for producers aiming to meet consumer demands for unadulterated, high-quality oils.

Different extraction methods have varying effects on oil quality:

- Cold-Pressing: This method is favored for its ability to preserve the natural flavor and nutritional value of the oil. It produces oils with superior taste and nutritional profiles.

- Solvent-Based Extraction: While efficient, solvent-based extraction may require additional refining steps to remove solvent residues and impurities, impacting the final product’s quality.

- Supercritical CO2 Extraction: This method is renowned for producing high-quality oils due to its ability to extract without heat, preserving the oil’s integrity.

Environmental Impact

The environmental impact of oil extraction is a growing concern. Solvent-based extraction, with its use of organic solvents, has raised environmental issues related to pollution and safety. As a result, there is a push for more sustainable practices in the industry.

Modern innovations, such as biodegradable solvents and energy-efficient equipment, aim to reduce the environmental footprint of oil extraction. Additionally, recycling and waste reduction efforts contribute to a more eco-friendly industry.

Conclusion

In the vast landscape of different oil extraction machines, making the right choice is paramount for achieving the desired quality and efficiency in your oil production process. Whether you opt for the time-tested expeller press machines, the flavor-preserving cold-press machines, or explore modern innovations like supercritical CO2 extraction, your decision should align with your production needs and sustainability goals.

As the demand for high-quality oils continues to rise, producers must prioritize both efficiency and environmental responsibility. By selecting the most suitable extraction machine and embracing eco-friendly innovations, you can play a vital role in shaping the future of the oil extraction industry.

In this ever-evolving field, where tradition meets innovation, the choice of extraction machine is not just a business decision—it’s a commitment to delivering exceptional oils while respecting the environment. So, embark on your oil production journey with confidence, armed with the knowledge to make informed decisions that benefit both your business and the planet.

Remember, the world of oil extraction is diverse, and there’s a machine tailored to meet your unique production needs. Explore, experiment, and elevate your oil production to new heights, one extraction at a time. The golden possibilities are endless.